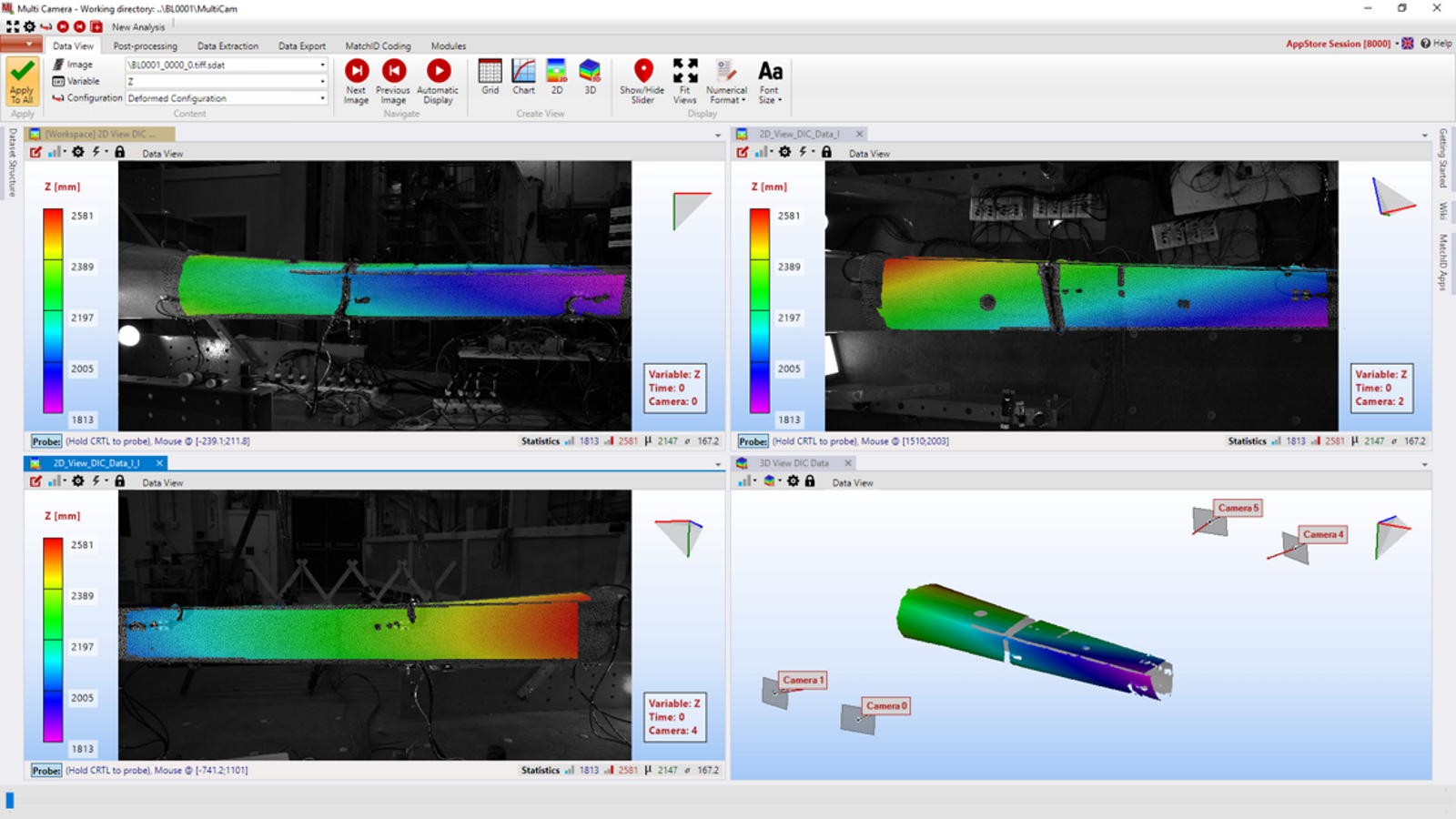

Digital Image Correlation

Quantitative Imaging Solutions

- 2D, Stereo and Multi-Camera Digital Image Correlation

- Shape, displacement and deformations of materials and structures

- Grid method based on phase-analysis for very small deformations

- A true engineering tool with total flexibility able to run in batch mode

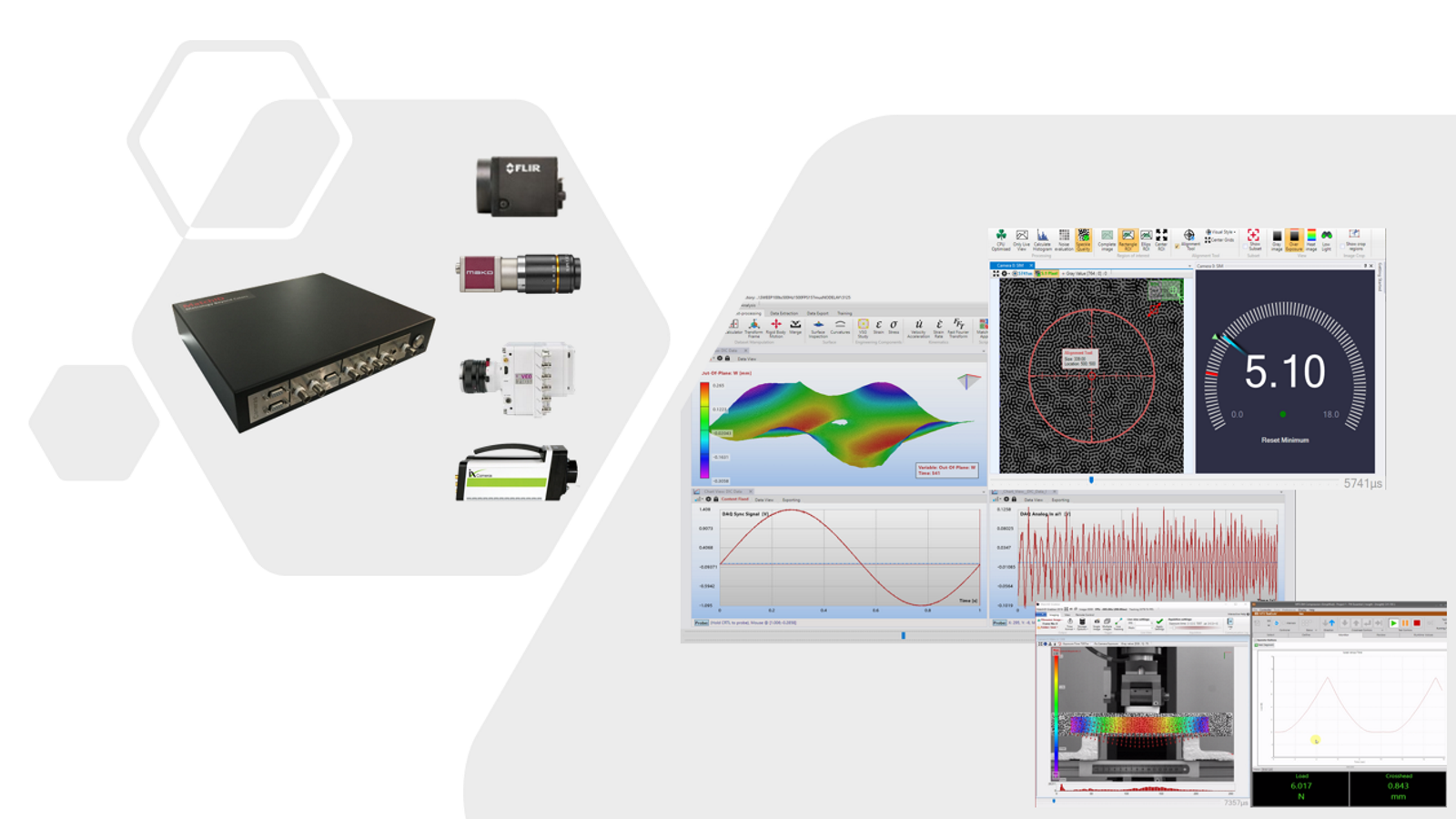

Optimized Testing

- Customized hardware according to your application

- Alignment, speckle analysis and focusing tools

- Vibration, Fatigue, Static or High-Speed

- Synchronization with external signals

- Real-Time DIC and feedback for external control

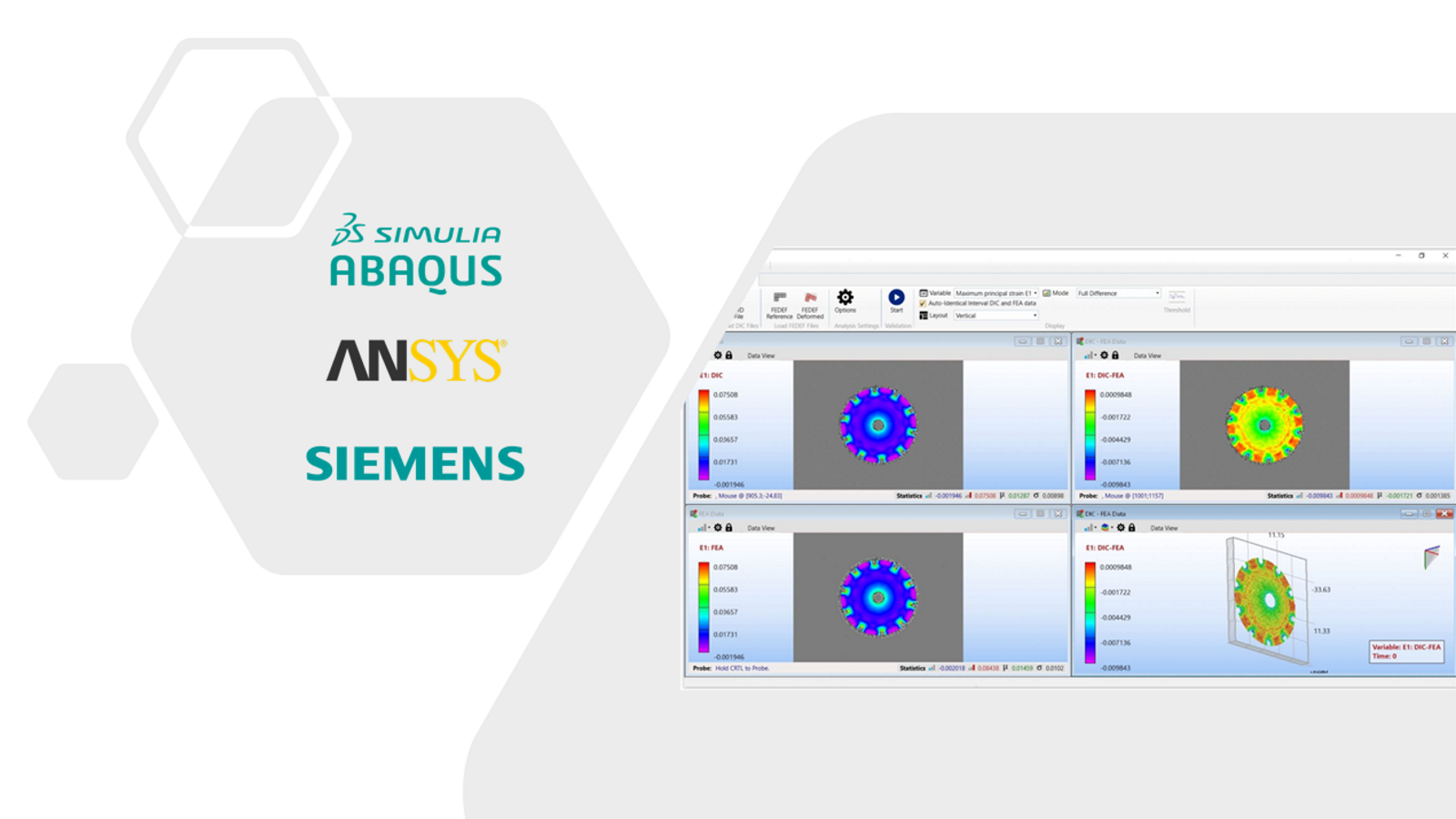

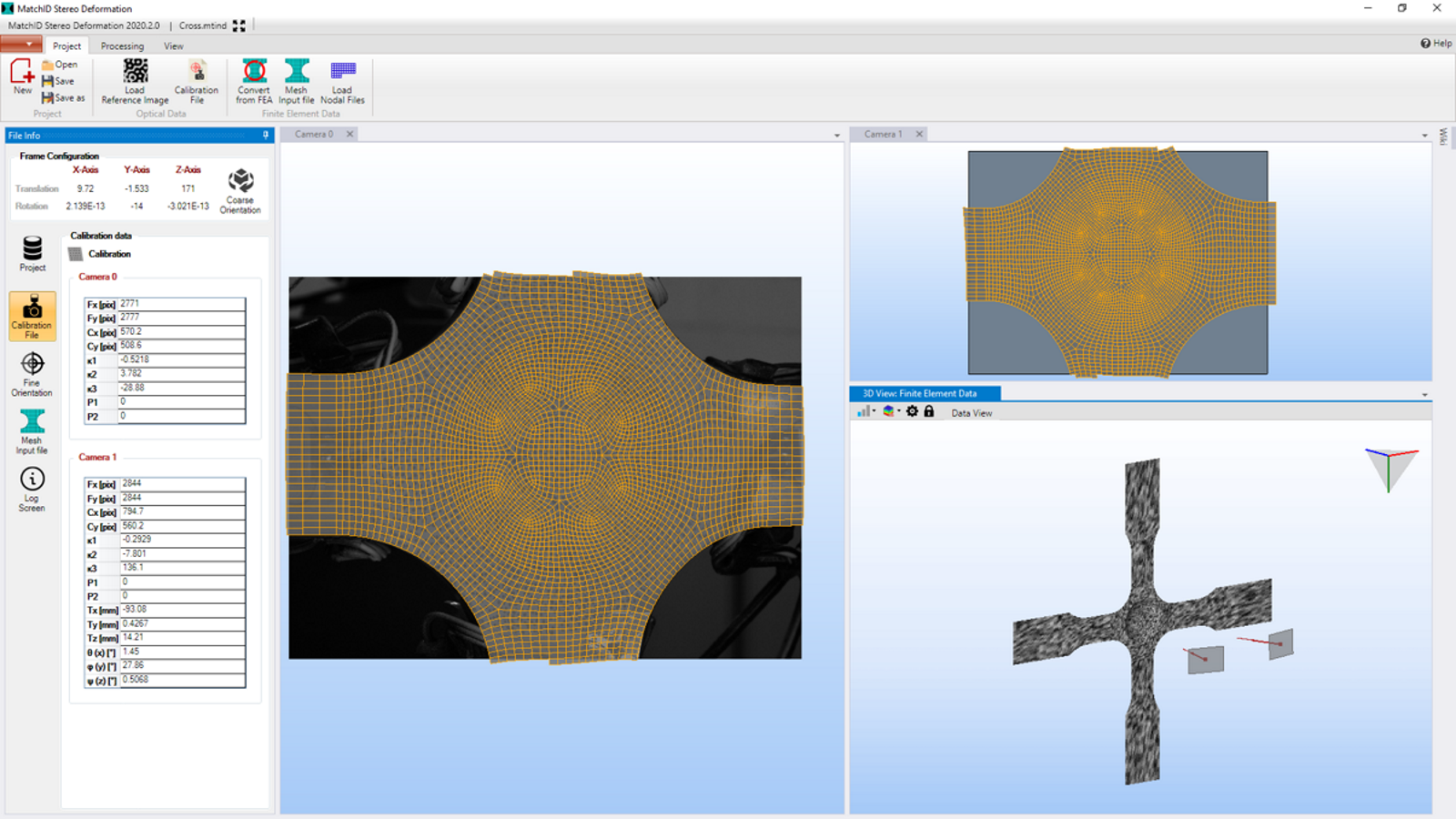

True digital twin - direct model validation

- Get quantified validation of your finite element simulations

- Levels the FEA data through the entire DIC engine via FEA-based images

- Generate full-field error and validation maps

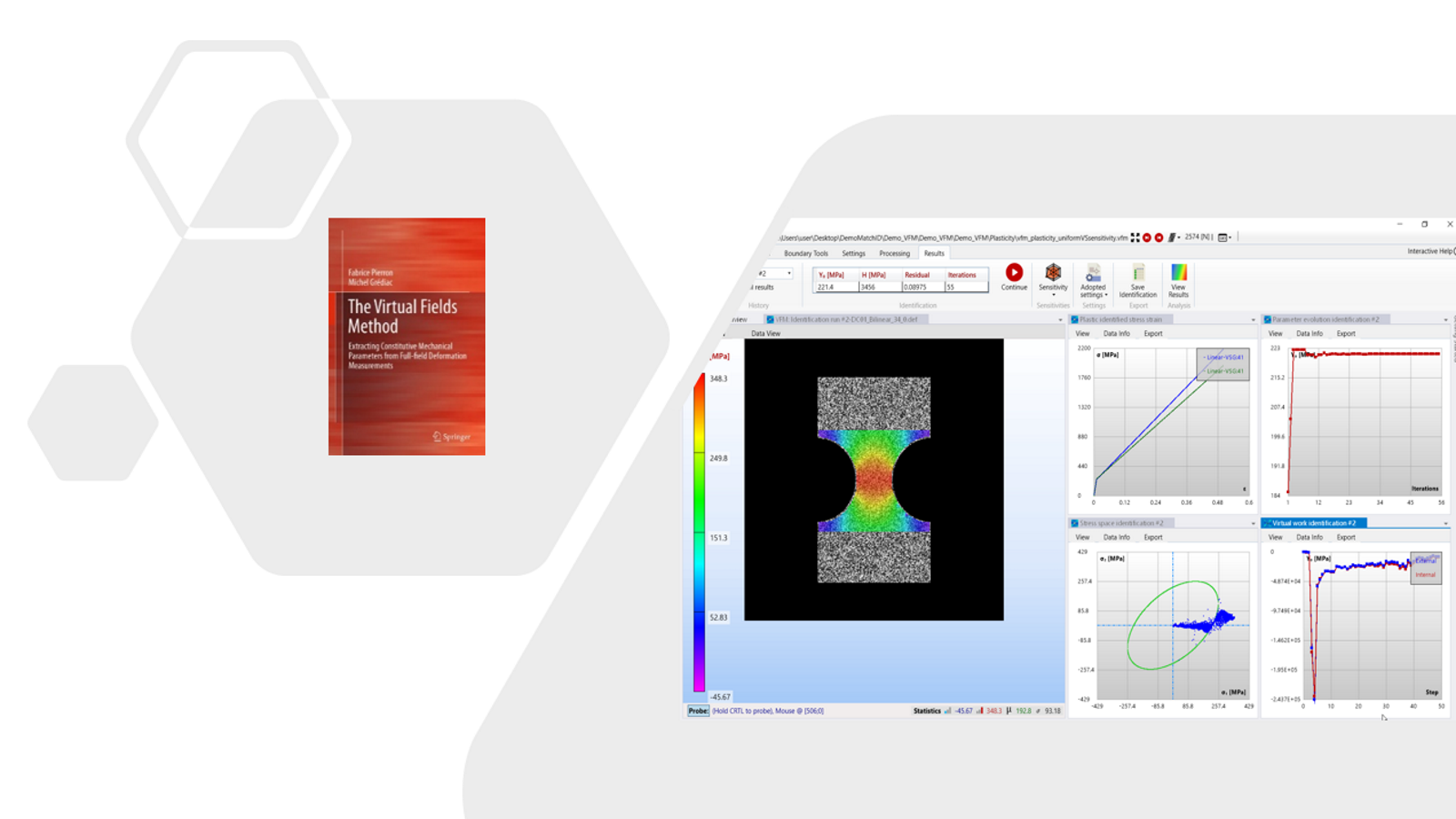

Identify mechanical material properties

- Seamless integration of the virtual fields method

- Reduced testing time and material usage

- Elasticity, plasticity, hyperelasticity, visco-elasticity, visco-plasticity

Intuitive and Elaborated Data Handling

- Dataset and multi-viewport concept

- Strain, velocities, accelerations, strain rates, ... and stresses

- FFT and modal analysis tools

- AppStore: Custom application development

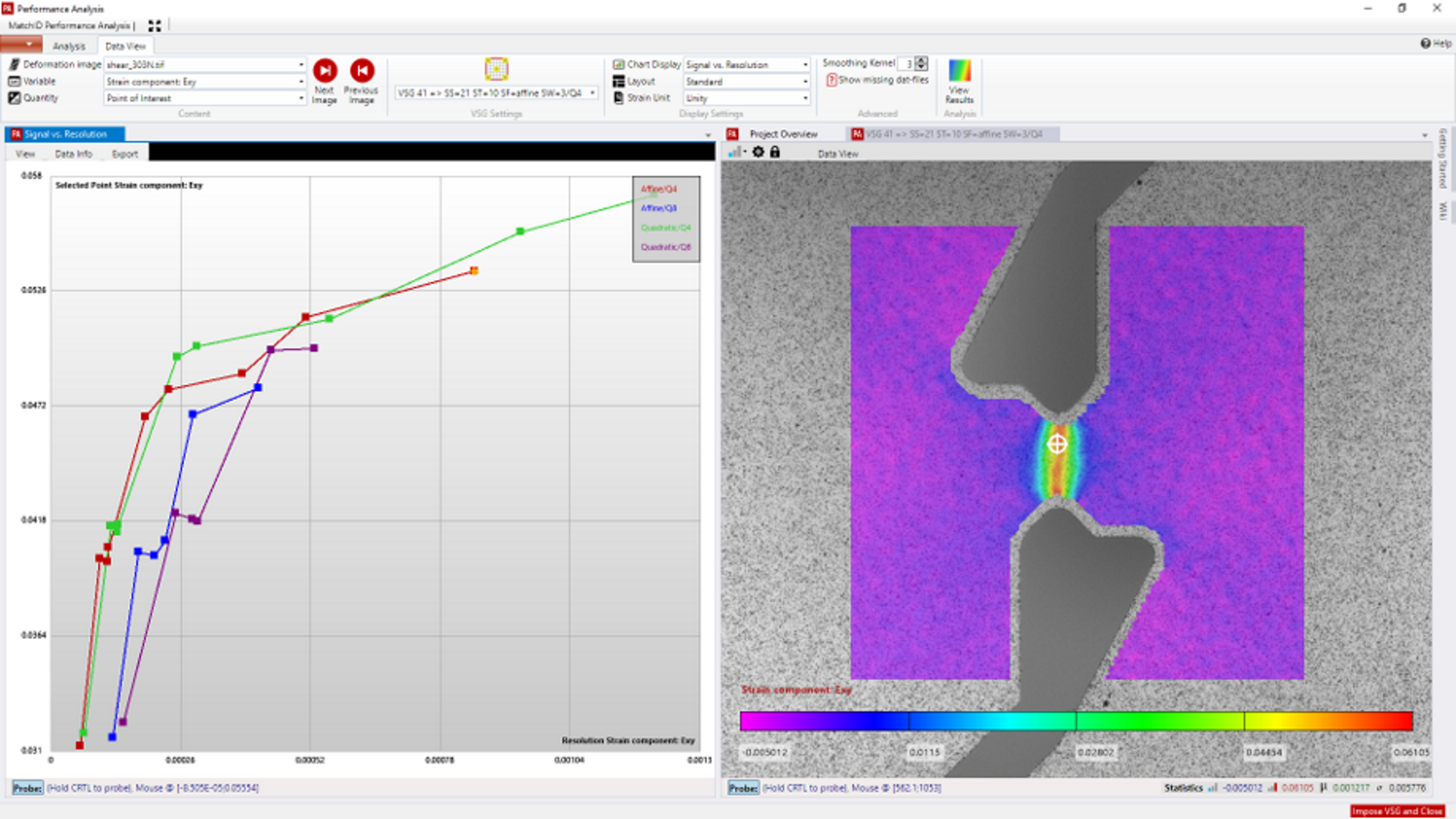

Performance Analysis

- A "design of experiments" for DIC

- Generate metrological charts to determine optimum DIC user setting

- Detailed insights into signal and noise evolution and dependencies

Uncertainty quantification and virtual testing

- Generate benchmark FEA-based synthetic images with known values

- Evaluate the inherent systematic error in DIC

- Create a virtual test campaign to optimize experiments