Running Projects

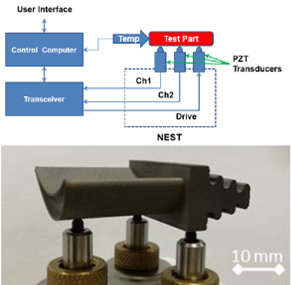

Resonam Project

We are involved in a recently approved Flemish Sim-Icon project entitled “Resonant-based material characterization for metal Additive Manufacturing“ also involving Materialise, Siemens Industry Software, KU Leuven and University Gent. This 3-year project will study the mechanisms and origins of variability in AM part quality. The effect of modifying printing conditions on the AM material will be investigated with vibrational NDT techniques as well as with various traditional material characterization techniques (metallography, X-CT, …). The developed framework will lead to a faster qualification of print process parameters as well as to a better AM material qualification. A key objective of MatchID here is to turn DIC into an essential toolbox for a continuously expanding AM market. This research project is a VLAIO-funded project with refernce HBC.2021.0798.

.png)

Tire NVH Project

The goal of this project is to improve both structure-borne and airborne tire noise prediction capabilities by creating novel test and simulation solutions and as such, support automotive OEMs and tire manufacturers for their vehicle NVH assessment and design, particularly in response to increasing importance of rolling noise in the electrification era. A hybrid approach will be adopted via integration of test and CAE tools for the capture of various stages of the rolling noise transfer chain. In this project, our main objective is twofold: (1) benchmark our multicamera DIC solution for sidewall 3D vibration measurements of rotating tires (2) make profound FEA validation studies via our FEVAL module. This research project is a VLAIO-funded project with refernce HBC.2018.2266.

.png)

RFCS project VFORM-xSteels:

Nowadays, the use of numerical simulations has become a mandatory step in engineering design and material processing optimization. The simulation market for the automotive industry alone exceeds 1 B€. Despite the size of the market and the regular use of simulation in the engineering design industry, obtaining reliable input data, especially the description of the material behaviour at different temperatures and strains is a constant challenge and has not been fully answered yet. A solution to this problem is highly required for both the engineering simulation users and providers.

A European project that aims to improve the confidence, precision, and robustness of the numerical simulations of steels parts through the development of new techniques for the determination of reliable input data has started on the 1st of July 2020. The 2.5 M€ project gathers five European countries, four universities, three industrial partners, and more than twenty researchers for the next four years. The project entitled “Toward virtual forming and design: Thermomechanical characterization of advanced high strength steels through full-field measurements and a single designed test” has joined the Universities of Aveiro (Portugal),Bretagne Sud (France),KU Leuven (Belgium) and Politecnica delle Marche (Italy) and the well-known companies MatchID and OCAS (Belgium) and DAF Trucks (The Netherlands) for the goal of developing procedures for the calibration of engineering material simulation software that would lead to stiffer, stronger, safer and lighter industrial parts. The EU contribution is through the research programme of the Research Fund for Coal and Steel – action RFCS-RPJ 2019.

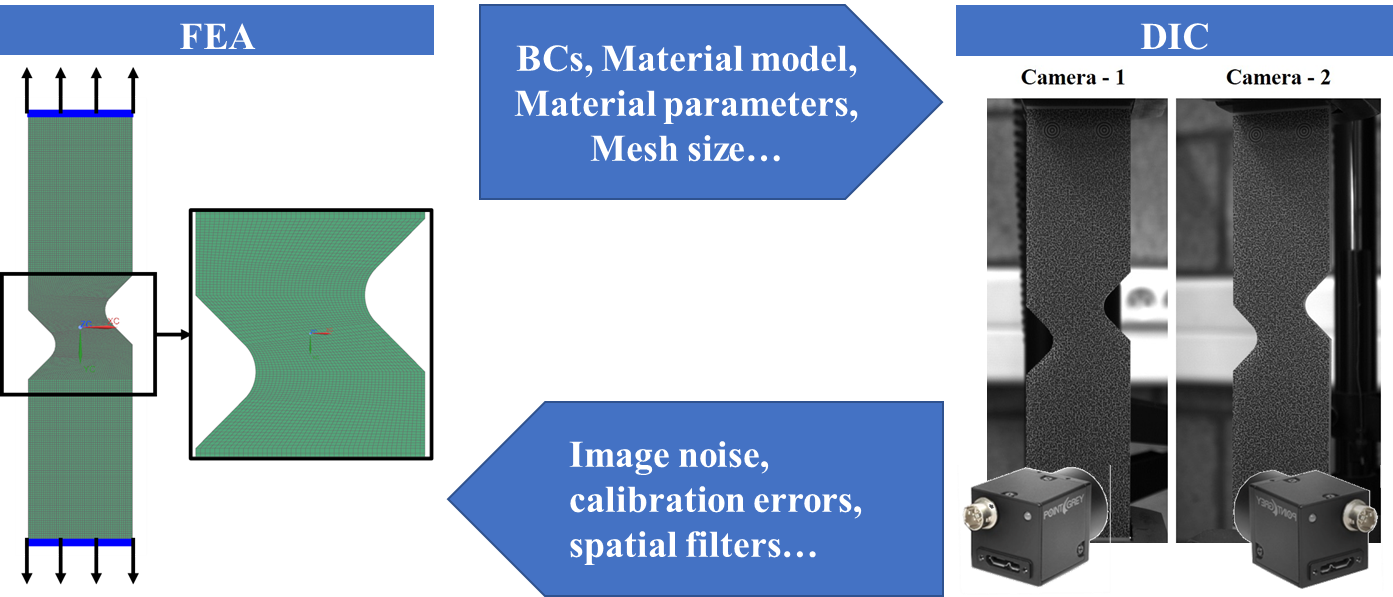

Development of DIC-based finite element model validation strategies

In this project, the focus is on studying the role boundary conditions in the FEA (BCs) play in the process of FE model validation. To disentangle the effect of discrepancies in BCs from the discrepancies in the modelling the material behaviour, a metric sensitive to only one of these factors is being studied. Carefully designed experiments, involving material with known and reliable behaviour, will be performed. Final aim is to quantitatively analyse the model validation errors originating from the BCs.

This research project is a VLAIO-funded Baekeland project with refernce HBC.2018.2105, and is a collaboration between MatchID NV and KU Leuven.

.png)

SimIcon ProPel project

Various manufacturing industries often rely on an engineering process that is based on an expertise built-up during several years of trial and error. Additionally, the gap w.r.t. existing simulation tools which often lead to complex workflows based on different simulation environments is recognized. Such complex workflow has important bottlenecks that this project will address:

- The overall tool usability makes the large-scale penetration of simulation tools cumbersome – this will be addressed by targeting an integrated end-to-end simulation solution for the selected combination of materials & processes

- Simulation tools typically rely on a top-down, reverse-engineering approach that only capture key physics in an empirical way – the physical fidelity is addressed by cross-linking 3 aspects: the manufacturing process aspects (e.g. thermal history),the material aspects (e.g. microstructural changes) and the required part performance (e.g. strength).

By addressing the above bottlenecks, the efficient and accurate assessment of the manufacturing process steps linked to part performance will be achieved by applying materials modeling.

The project will lead to important economical and operational advantages for different industries using thermoplastic materials (including composites). The aim is to provide industries an integrated workflow that doesn’t require management of a complex toolchain, typically composed by three different simulation tools for each aspect (material, process and performance) often made by different software providers. This research project is a VLAIO-funded project with refernce HBC.2019.0094.